Case Study

Automatic Lubrication in Waste Water Industry

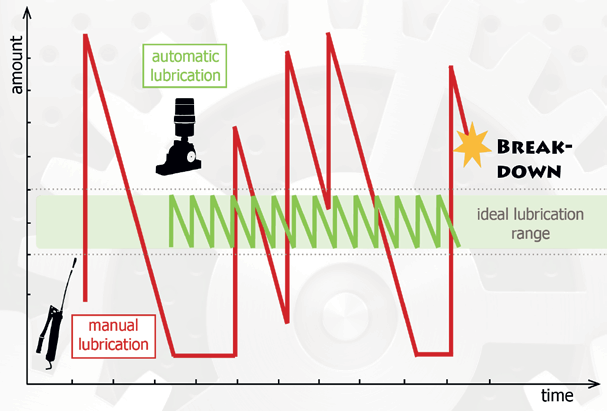

Why automatic lubrication?

Lubricators replace costly manual lubrication.

■ Time saving

■ Increasing work safety

■ Lower lubricant consumption

■ Less machine downtime

■ Reducing energy costs

■ Reducing risk of contamination

Challenges

■ Contamination

■ Safety

■ Costs

In the waste water industry the access to many lubrication points is burdensome or dangerous. Manual lubrication is inconvenient due to spacious facilities and a large variety of different lubricants and applications. Contamination’s as dirt, water, phosphate and other chemicals lead to high exposure on guides, chains and bearings.

Scopes of application

■ Sedimentation tank

■ Clarifier

■ Sand removal

■ Pumping station

■ Compressor

Lubrication points -Single

Ambient temperature -20 °C to +60 °C

Working voltage – Battery

Max. operating pressure -10 bar (145 psi)

Indirect installation – Up to 4 m*

Max. run-time – 24 months

Setting – 1, 3, 6, 12, 24

Filling – By yourself or on customer request

Reusable drive – Yes

Self-refilling – Yes

Time / pulse control – Time mode

Lubrication points -Single

Ambient temperature -20 °C to +60 °C

Working voltage – Battery or 24 V

Max. operating pressure – 7.5 bar (109 psi)

Indirect installation – Up to 2.5 m*

Max. run-time – 24 months

Setting – 1-12 (stepless)

Filling – By yourself or on customer request

Reusable drive – Yes

Self-refilling – No

Time / pulse control – Time & pulse control

Lubrication points – Multiple

Ambient temperature -20 °C to +70 °C

Working voltage – Battery or 24 V

Max. operating pressure – 70 bar (1015 psi)

Indirect installation – Up to 6 m*

Max. run-time – 36 months

Setting – 1-36 (stepless)

Filling – By yourself (Oil) or on customer request

Reusable drive – Yes

Self-refilling – No

Time / pulse control – Time & pulse control

Contamination

■ Automatic lubrication lowers the risk of contamination

■ Lower machine wearing despite chemical loaded environment

Costs

■ Lower energy costs

■ Time saving

■ Sustainable by multiple refills

Safety

■ Indirect installation possible

■ Central controlling and monitoring in an user-friendly environment